QR monitoring system

Between we were preparing our new catalogue, we created QR monitoring system. This system overcame the limit of labels and other printings. We concentrated all information of products during production procedures in QR codes, for example, production date, operators, quality test etc. Customers can check it easily just by scanning codes. This method is to the best of both worlds. On one hand, it is convenient for controlling the quality by customer, on the other side, it is a good idea for tracking and find out error to our side. When there is problem on some of our products to customer side, we can get the information of products from this code easily, who produced it on which date, what materials used for it, how it was made, how it was tested, who tested it. With these information, we can make clear analysis of problem and find out what is wrong soon. We will give quick response to customer’s complaint and provide solution. Same time, after the experience of this time, we will improve. We will provide better and better products and service to customers in the future. QR monitoring system also ensures the high efficiency management of our production.

AQL HABERLER

1.03.2016

1.03.2016

New Investment to TURKEY / BURSA

we founded our fac tory in European Area. It is located in Bursa, a biggest city of Turkey. That means all our manag

20.05.2016

20.05.2016

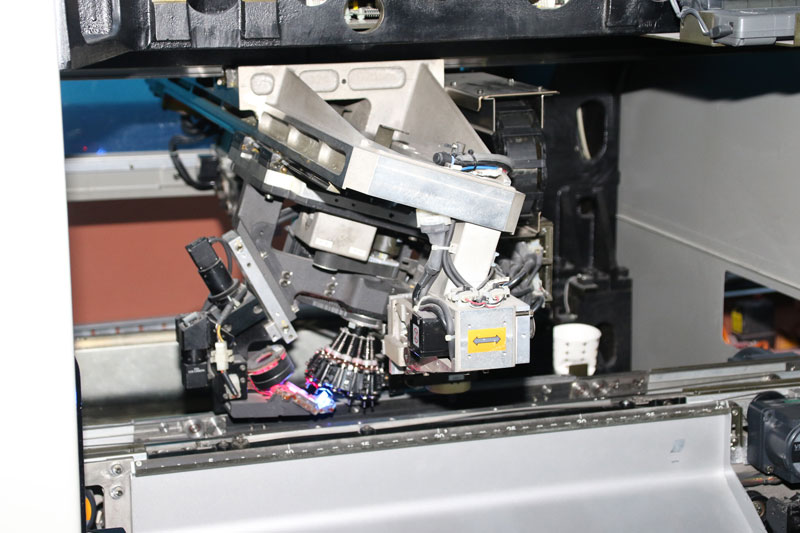

We build a new high technology laboratory

We built our high technology laboratory with optoelectronic measuring system, including HAAS-2000HIGH ACCURACY ARRAY SPECTRORADIOMETER, 1.5M INTEGR

6.06.2016

6.06.2016

QR monitoring system

Between we were preparing our new catalogue, we created QR monitoring system. This system overcame the limit of labels and other printings. We concent

17.07.2016

17.07.2016

New agreement with WAGO for automation solutions

we had agreement with WAGO for automation solution. They are our official partner now. WAGO is an Germany company who is the leader in automation sol